IrvesBMW

Members-

Posts

309 -

Joined

-

Last visited

-

Days Won

1

Everything posted by IrvesBMW

-

After a brief period of time, the vehicle starts operation in an optimal manner, exhibiting a seamless performance devoid of any peculiar speculations. However, it experiences a decrease in power output beyond the speed threshold of 40 miles per hour. There is an absence of smoke emissions in the exhaust. Upon using the BimmerLink APK on my smartphone, I saw that the Diesel Particulate Filter (DPF) exhibits a soot level of 87%. However, it indicates that the regeneration process was completed 235 km prior and does not need further regeneration. This occurrence is peculiar. Today, I will be engaging in the task of changing the engine oil in order to observe the potential outcomes that may arise. I express my gratitude for your assistance.

-

The absence of evidence in INPA+ (or maybe ISTA+) does not necessarily imply the absence of either of the two occurrences.

-

However, it is important to understand the process by which diesel fuel might get mixed with engine oil. I used the INPA+ software to assess the condition of my injectors, and I can confirm that they are functioning optimally. I express my gratitude for your assistance.

-

I conducted a verification process using the application Insta+. There is no issue related to the injector. There are no reported issues with the gasoline pump.

-

I have verified that the coolant level is within acceptable parameters. There is no evidence of oil contamination seen on the coolant bottle and oil cap.

-

Yes, I have obtained an item that has reached its maximum level. At one point, it had slightly beyond the average level. I did not add anything. One intriguing aspect is to the factors that contribute to the elevation of the level. I express my gratitude for your assistance.

-

Greetings, I would like to bring to your attention that an unexpected message has shown on the iDrive system of my BMW E70 4.0d xDrive LCI model. The engine oil level is too elevated, resulting in a decrease in the power output of my vehicle. Do any of you have insights on the causes of this occurrence and any solutions to address it? I express my gratitude for your assistance.

-

I purchased the most expansive radiator available, which spans the whole vertical length, although its effectiveness remains suboptimal. Given that the ambient temperatures exceed 86°F, it is unsurprising that the efficiency is compromised. Regarding the head gaskets, the original ones were measured to have a size of 94mm.

-

I will proceed to get the measurements from the gaskets that have been removed, and thereafter verify their accuracy. Regarding the charger kit, the specific model I own (VF620) is equipped with a charge cooler. In warm climatic conditions, I have seen that the effectiveness of the system is compromised due to the consistently elevated intake air temperature (IAT) exceeding 60 degrees Celsius. This observation is disheartening. The air cooler is located inside the aluminium intake plenum, which is positioned above the engine. I am curious in the potential temperatures that may be attained in the absence of a charge cooler.

-

I have been contemplating the installation of thicker head gaskets. The Mahle PowerPak forged Pistons used in the engine have a diameter of 92mm and a compression ratio of 12.2. Additionally, the cylinder heads will undergo a surface refreshing process. The engine is further fitted with the VF620 supercharger, which provides a boost of 7 psi. What recommendations do you propose? In addition, during my browsing endeavours, I came across a product from Cometic that provides a thicker alternative. However, it is worth noting that these options are available in dimensions of either 93 or 94 mm, while the original product is 92 X 0.027 inches. Is it OK to get a 93 or 94mm component in lieu of a 92mm component? I express my gratitude.

-

Thank you once again for your response. Considering my decision to get the Mahle PowerPak forged pistons, which possess a distinctive coating, I am contemplating the possibility of abstaining from piston machining and instead using a thicker head gasket. What is your opinion on the matter at hand? Regarding the rod bearings, would you suggest the Lead-indium bearings from Mahle MotorSports as a suitable option? I kindly want your recommendation on the matter of valve seating. I express my gratitude one again.

-

Thank you for providing your feedback. I really like the opportunity to engage with the S65 engine as a novice. Regarding the increase, it will range from 7 to 9 pounds per square inch (psi). I discovered a head gasket with a thickness of 1.3mm, which I am contemplating using in conjunction with Mahle pistons that have a compression ratio of 12.2:1, as opposed to the original ratio of 12.0:1. This adjustment is intended to compensate for the anticipated refreshment of the cylinder heads. Regarding the valves, I want to do a minimum of triple valve angle seating. However, I will consult the engineering company with whom I will be collaborating to inquire about your recommendation. I kindly request that you provide further information, as it would be very appreciated. Regarding the valve spring kit, could you recommend any other manufacturers or configurations? Would you recommend that I pursue an other course of action? I express my gratitude one again.

-

Following a year of using the VF620 Supercharger Kit on my 2008 BMW M3 e92, I have made the decision to dismantle the engine and implement enhancements aimed at enhancing its reliability and maybe achieving superior performance. I am composing this essay with the intention of seeking recommendations on the optimal components to include in my engine repair. The vehicle will be used for both street and racing purposes. Please provide me with your sincere evaluation and recommendations. I own a pre-existing collection of Arrow connecting rods. The crankshaft will achieve complete balance with the acquisition of all the necessary components in accordance with the specifications. The further enhancements that I want to install on my S65 engine are as follows: A comprehensive set of valve springs that have been enhanced for improved performance. I have observed the SCHRICK HIGH-PERFORMANCE VALVE SPRING KIT. In your opinion, do you believe them to be the optimal choice? Could you recommend other brands? I am considering the use of a complete piston set manufactured by Mahle. However, I am now uncertain as to whether I should choose for the 4032 or 2618 forged pistons. Additionally, I am also undecided between using the original 12.2:1 compression ratio or the alternative 10.1:1 compression ratio. The bores were meticulously measured and are in excellent condition, with a bore size of 92mm. Could you kindly provide advice, please? I am considering the use of 12.1:1 compression ratio (CR) pistons in conjunction with a 1.3mm thick head gasket sourced from FCP Engineering, with the intention of slightly reducing the compression ratio. Kindly provide guidance or recommendations. The topic of discussion pertains to rod bearings. Presently, I am examining two potential options for bearings: the polymer-coated bearings manufactured by King Racing and the lead-indium racing bearings produced by Mahle Motorsport. Kindly provide guidance or recommendations. Which options would you recommend? Could you kindly provide any other recommendations? The whole gasket set is sourced from either Elring or Victor Reinz. Which option would be selected? I am replacing the original head bolts with ARP head studs. Kindly provide guidance or recommendations. The following enhancements are under consideration for implementation during the engine overhaul process. Could you provide any recommendations for the use of the VF620 supercharger kit from VF Engineering in street/race scenarios? Please do not hesitate to provide me with alternate items to the ones mentioned above. Additionally, if you are aware of any websites that are now giving discounts, I would really appreciate it if you could kindly indicate them. I express my gratitude in advance.

-

The BMW M Performance electronic steering wheel does not need any programming, as per my understanding.

-

Hot Middle Advisor? One way traffic only...

IrvesBMW replied to QuirkEinstein's topic in General Discussions

I have acquired a collection of 19-inch wheels for my BMW 750i, which have been equipped with All Season tires in preparation for winter conditions. The quality of the ride exhibits a marginal improvement, yet it falls short of the significant disparities that are being expounded upon inside this discussion. Perhaps the reason for this might be attributed to the possession of Executive Drive Pro. -

Assistance Requested for X6 E71 Basic Sound System

IrvesBMW replied to DreamWeaver's topic in General Discussions

I used my creative problem-solving skills to arrive at a solution. I retrieved one of the original equipment manufacturer (OEM) speakers that I had previously removed and proceeded to establish a connection with the wiring harness, assuming that it was the designated location for the speaker wire. I used the fader and balance controls to ascertain the identification of each speaker. The task has been successfully completed. -

Assistance Requested for X6 E71 Basic Sound System

IrvesBMW replied to DreamWeaver's topic in General Discussions

I have had significant challenges throughout the latter phases. The front door speakers have been successfully attached, and I have documented the wire colors for future reference. The colors under consideration are yellow and yellow/blue. The subject matter under consideration is the concept of "left," specifically in relation to the colors white and white/blue. I have removed the CCC iDrive and intend to sever the input and output cables for the new speakers. This is the location where I anticipated seeing a pair of wires, one white and white/blue, and another yellow and yellow/blue. Nevertheless, I do not own the aforementioned wires, since there are many other connections connected to the rear of the machine. I am now facing a significant impasse. Could someone kindly provide answers to two questions I have? Does the presence of a BMW vehicle between the speaker and the head unit result in any alteration in the color of the speaker wires? Could someone please provide information on the specific cables located in the front left and right areas? I would want to express my gratitude in advance. -

Assistance Requested for X6 E71 Basic Sound System

IrvesBMW replied to DreamWeaver's topic in General Discussions

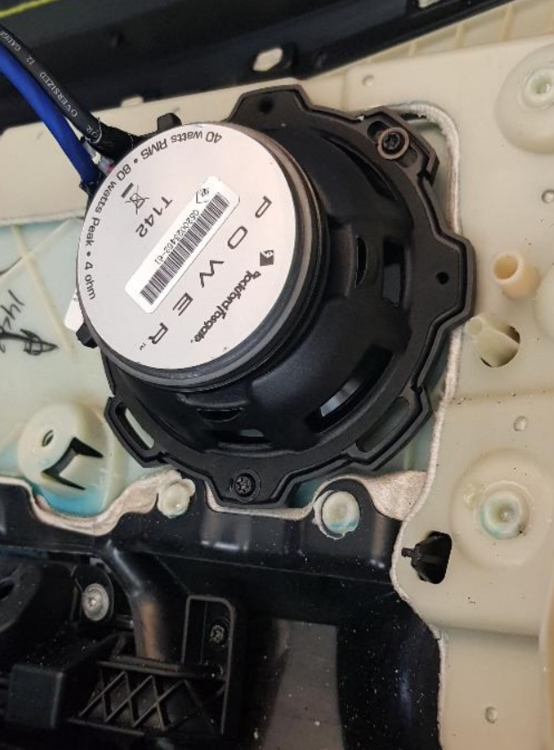

Today, I successfully completed the installation of my Rockford Fosgate front speakers, which have a diameter of 4 inches. The speaker, although being 4 inches in size, has much larger cone area and depth. Remarkably, the mounting holes exhibit alignment with those of the RF's as a result of the basket design. In order to accommodate the cone excursion adequately, it was necessary to remove a portion of the plastic by grinding. Once the door panel was joined, it was seen that it protruded more, but it was successfully reinstalled without any difficulty. The operating system Windows, along with other related software, operates without any noticeable issues. The audio quality has much improved; however, I have not yet established a connection between these components and the amplifier. Currently, they are still operating via the head unit. Even in the absence of other installations such as amplifiers, these speakers are capable of fitting into the system and producing superior sound quality compared to the original stock speakers. The approximate cost of a set is around $55. -

Assistance Requested for X6 E71 Basic Sound System

IrvesBMW replied to DreamWeaver's topic in General Discussions

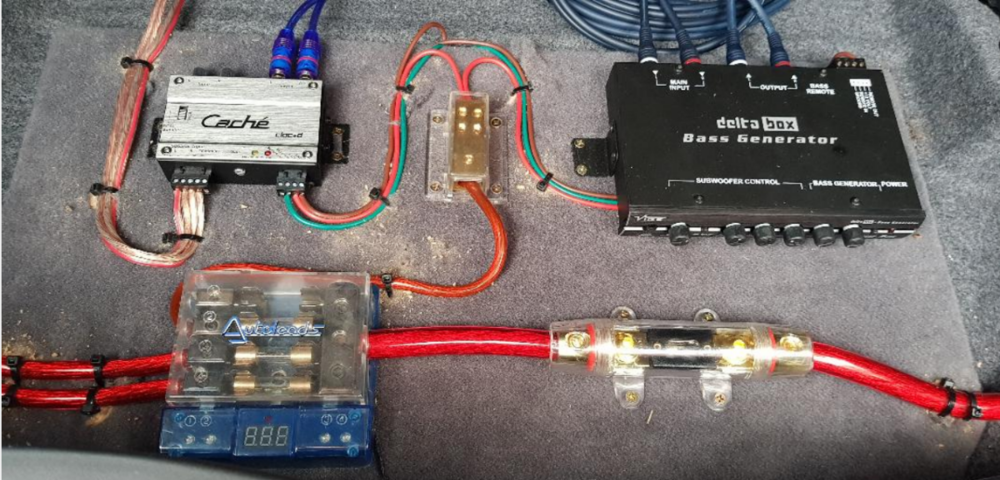

The first step should include identifying the head unit in question, specifically whether it is a CCC or CIC. Conducting an online search to determine the corresponding screen that aligns with the identified head unit is recommended. Additionally, may I inquire about the volume of your audio system? I have come upon a little piece of information that may be of use. If tweeters are absent from the front doors, it may be inferred that the audio system is classified as "Base." If tweeters are present in the front doors and there is an absence of speakers in the rear "D-Pillars" of the X5, it may be concluded that the audio system in question is categorized as "Standard (Hi-Fi)." If there are speakers present inside this particular region, it may be inferred that the audio quality is of a premium kind, specifically categorized as "Premium (Top Hi-Fi)." If one has a high-fidelity (Hi-Fi) or top-tier Hi-Fi audio system, it is likely that an amplifier is present, often located in the passenger side of the vehicle's trunk. One may get high-level input from that source. In the event that one has a foundational or rudimentary configuration like to mine, the reception of information at a higher level is facilitated by the posterior aspect of the primary control unit. Subsequently, the high-level signal is sent to a high-low converter, resulting in the generation of pre-outs. If one has a filtered signal, it is advisable to use a subwoofer equalizer/crossover or verify that the amplifier being used possesses a proficient crossover and the capacity to enhance frequencies. Failure to do so may result in the transmission of a signal lacking in bass to the amplifier. The following is a description of my experimental arrangement: I use cache cloc+d as my line converter in order to optimize bass performance. Additionally, I employ the Vibe Delta Bass generator to fine-tune the bass output. -

Assistance Requested for X6 E71 Basic Sound System

IrvesBMW replied to DreamWeaver's topic in General Discussions

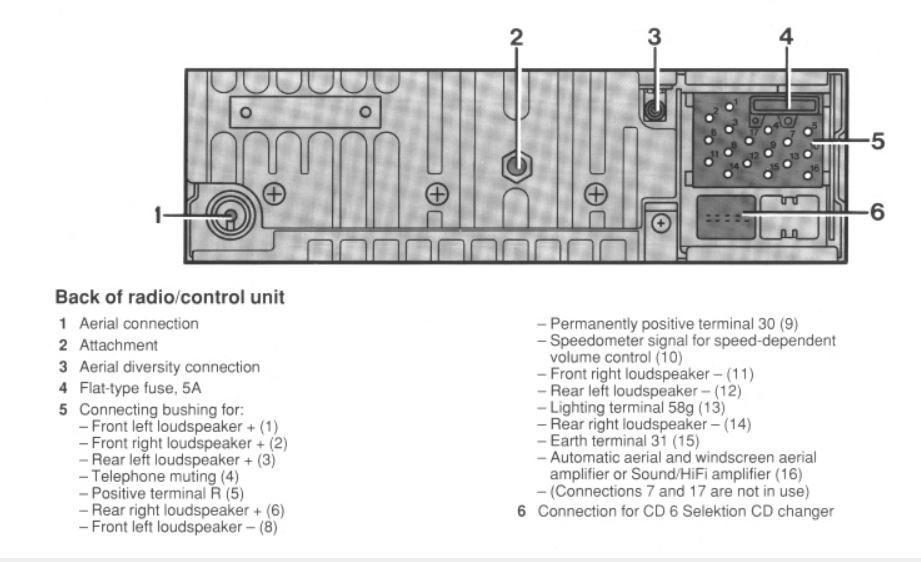

Could you please provide further information? I own a CCC unit and have successfully obtained a wiring schematic for such equipment, which conveniently delineates the requisite speaker cables. I will proceed to access the dashboard and ascertain if the components I own align with the provided diagram. After examining the CCC Idrive unit and referring to the diagram provided below, it is evident that the diagram does not correspond to the CCC Idrive unit. -

I am contemplating the acquisition of a dashboard camera for my E92 vehicle, although I am encountering difficulty in locating a good option. I am disinclined to remove it from the vehicle each time I depart due to the inconvenience it entails. However, I am also reluctant to keep it visible, since this increases the likelihood of theft. Ideally, the preference is for a camera lens with an extended cable, allowing for the majority of the equipment to be stored in the glove box while just a discreet camera remains visible. However, it seems that such camera configurations are not readily available, particularly at a reasonable cost. An alternative suggestion is using a dated mobile device in conjunction with a USB webcam or endoscope that is connected through a USB port. The primary aspect of concern in this context is to the quality of the images. Dash cameras are capable of capturing high-quality images, particularly in low-light conditions, due to their superior night vision capabilities. Additionally, these cameras provide a wide-angle perspective, which further enhances their visual coverage. Consequently, it may be challenging to locate a webcam with equivalent specifications. According to an acquaintance employed in law enforcement, the incidence of dash cam theft is rather infrequent, although the prevalence of stolen satellite navigation systems is much higher. The rationale for the comparable pricing of sat navs and dash cameras remains unclear. One could have anticipated dash cams to possess more appeal, given that sat navs are considered outdated technology due to the prevalence of Google Maps. I am curious about the practices and behaviors of others. Has an inconspicuous solution been discovered or do the majority of individuals just retain their dash cameras in place, relying on the chance that they will not be stolen?

-

I express my gratitude for the responses received and intend to undertake the suggested actions during the next week. I am aware that red calipers are popular among individuals, but, they do not align with my own preferences. Although I expressed my own opinion by using the terms "awful" and "hideous," it is important to acknowledge that aesthetic preferences vary across individuals. I have engaged in unconventional behaviors with my automobiles at instances characterized by both impulsive and rational states of mind.