keithmerc220

Members-

Posts

251 -

Joined

-

Last visited

Everything posted by keithmerc220

-

I’ll be honest, my delivery was two days later than originally expected when I purchased my first repo car, which did make me anxious at the time but Lamsam Logistics called me as soon as they knew there would be a delay and kept me updated. When the car arrived, it was flawless. So despite the wait, I was very happy with the outcome.

-

Hello there, people. I require assistance or guidance on a 2012 BMW F30 equipped with a 2.0L N47 engine. When reversing, it produces several thudding noises from either side. It appears to originate from an impact beneath the vehicle. While in the vehicle, I replaced the passenger side tension strut/control arm (the one with the large hydraulic bushing) due to a defective ball joint, hoping it would resolve the issue; but, it did not. It appears to occur exclusively while making a turn in either direction while proceeding straight. I have not observed it. The sound is unpleasant, resembling the impact of striking something beneath. Any suggestions or input would be highly appreciated. Thank you.

-

Artificial Intelligence proposes this. The purple square featuring a vertical line and a star symbol signifies a sensor or electronic control unit alarm in your Mercedes W205. This is a generic alert, frequently associated with a malfunction in a particular system, and it is generally accompanied by a supplementary message on the dashboard display that delineates the precise issue. Proposed Measures Verify for a supplementary message: The primary dashboard interface will probably exhibit language (e.g., "Inoperative", "Refer to Owner's Manual") elucidating the particular system experiencing the malfunction (e.g., Active Brake Assist, ESP, or a designated sensor). Reinitialise the vehicle: The problem may occasionally stem from a transient electronic malfunction, which can be rectified by powering down the vehicle, removing the key for around 30 seconds, and then restarting the engine. Exercise caution while driving: This symbol, when displayed in yellow or purple, indicates a caution rather than an immediate red-level safety concern, allowing you to proceed to a safe place or an authorised repair facility. Seek the assistance of a technician: Due to the symbol's lack of specificity, a diagnostic scan instrument (OBD-II scanner) is required to ascertain the exact error code and underlying problem.

-

The boot of the Mercedes W211 opens but does not elevate.

keithmerc220 replied to keithmerc220's topic in General Discussions

Mine is equipped with spring assist; I merely need to determine how to access it for adjustment. -

The boot of the Mercedes W211 opens but does not elevate.

keithmerc220 replied to keithmerc220's topic in General Discussions

Yes, it automatically elevates; however, for the past two months, it has not done so. I observe that it possesses springs on both sides. -

😃

-

unlike certain individuals encountered in recent months or years, such as trolls or spammers

-

I am perplexed as to why the installer from whom I acquired the Head Unit was unable to assist me with that; I would have willingly given a nominal fee, as the unit cost me Rs29,500, inclusive of installation. I require calibration for the 360; however, I lack the calibration cloth, and the three-week wait is intolerable for me. I will refrain from suggesting anyone to him and disapprove of his manner of communicating with clients. Another objective is to transmit the CAN messages from the Steering Angle Sensor (SAS) to the Head Unit for dynamic trajectory, a task I am now undertaking that will require more time.

-

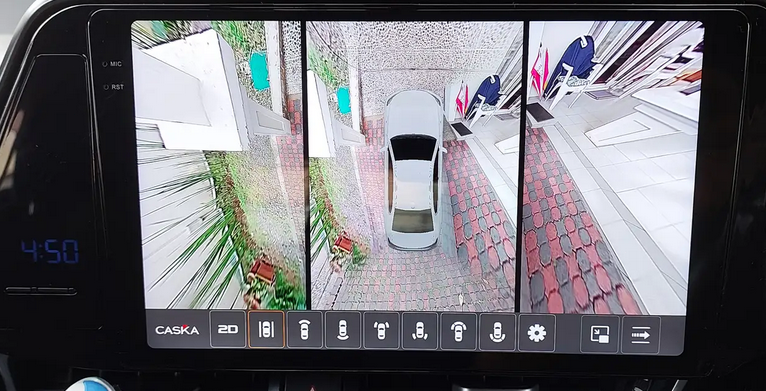

Attached are several images of the Caska S70 Head Unit installation. Calibration remains outstanding as the installer lacks a suitable flat surface; he will calibrate a batch in the second week of December. He should have notified me about that sooner; I am rather displeased. Efforts are ongoing on my part to transmit the Steering Angle from the CAN bus to the Head Unit UART interface.

-

The pinout of the harnesses is located here. I discovered a YouTube channel by Mr. Rajeev Velikkal, who has effectively interfaced with the body CAN system to retrieve steering angle readings from the Steering Angle Sensor (SAS). In his project, the steering angle assists in aligning the front wheels when the vehicle is placed in Park by emitting an audible beep if the steering wheel is misaligned. He not only reads the CAN bus but also transmits CAN messages/frames to lock or unlock the car and to activate the Brake Hold feature when reaching a specific speed. He has additionally published his code on hackster.io. His project has inspired me to facilitate the dynamic trajectory on the Caska S70 Head Unit I am installing for the 360-degree surround vision.

-

This is the second unit; the first was defective and replaced under warranty. The back camera is the third one; one was replaced under warranty, and I replaced the other two myself. We are dissatisfied with this component of the vehicle and will upgrade it by next Monday I am encountering an issue with this installation: the dynamic trajectory lines are nonfunctional since the head unit harnesses lack the CAN L and CAN H wires necessary for the CAN bus to transmit the Steering Angle.

-

I wish to activate the Dynamic Trajectory feature in the 360 functionality of a Caska S70 Head Unit installed in my wife's Toyota C-HR model NGX10R-AHXNX. To enable this feature, I must transmit the Steering Angle Sensor data from the CAN bus to the Head Unit. The vehicle was produced in Turkey and acquired new from the local Toyota dealership in Mauritius. The vehicle was equipped with a Caska head unit installed by the dealer instead of an OEM head unit. It was equipped with a back camera and Bluetooth for telephone pairing.

-

Your observation regarding the heat is valid. I may need to switch to LED; my current light functions but lacks brightness. If your experience is similar, I must either transition to LED or accept the current condition.

-

Hello, do you know where I can obtain replacement bulbs? My current bulb is functioning, but the display lacks brightness. It is a 1.2W bulb, although it may require a higher wattage for improved illumination.

-

New automobile? 318i or 318d? Or incinerate my funds?

keithmerc220 replied to ianwh4's topic in General Discussions

I possess a 2007 BMW 320d with 107,000 miles that I need to sell, but it is somewhat distant. The lacquer has deteriorated on the bonnet and roof, however the car has received meticulous care over the past 15 or 16 years. I do not desire much for it. -

New automobile? 318i or 318d? Or incinerate my funds?

keithmerc220 replied to ianwh4's topic in General Discussions

What is your location? -

I understand your perspective and your justified caution. My perspective is that a car valued at over £60,000 is unlikely to be test-driven by seventeen-year-olds, though I may be mistaken. According to TDudette, the running nowadays is not really necessary. Is it advisable to perform an oil change following the break-in period?